Vibration Sensors Selection Guide Types Features Applications Circuit Diagram

BlogVibration Sensors Selection Guide Types Features Applications Circuit Diagram In industrial automation, vibration sensors monitor the status of machinery and equipment on the production line in real time. If abnormal vibrations are detected, the sensor triggers an alarm, prompting the operator to check the equipment's condition. This helps avoid unexpected downtime and ensures smooth production processes and consistent

In industrial automation, sensors are essential for monitoring various parameters, such as temperature, pressure, humidity, motion, and proximity, ensuring optimal performance, safety, and compliance with quality standards. Types of Sensors Used in Industrial Automation. Vibration Sensors. Working Principle: Types of Vibration Sensor. Now that we know what vibration is, let's look at the different types of sensors to monitor vibration. First, we will talk about an accelerometer. 1. Accelerometer. Accelerometers are devices that measure the vibration, or acceleration of motion of a structure. We'll also discuss their diverse applications, including industrial automation, automotive safety, and consumer electronics. Finally, we'll demonstrate how to integrate a vibration sensor with the ESP32 microcontroller using GPIO 18, showcasing practical examples of real-time data collection and analysis.

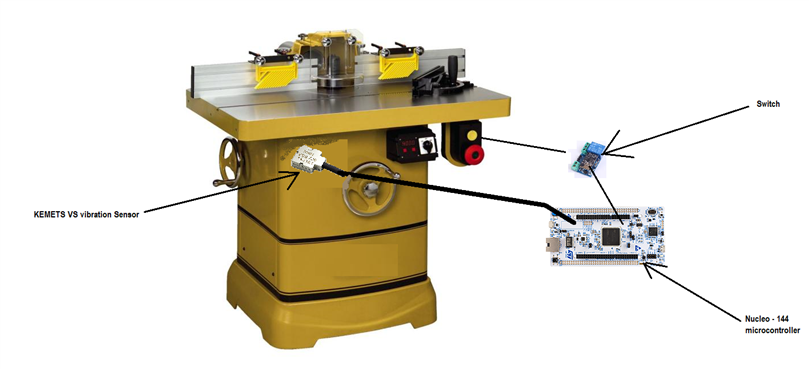

Complete Guide to Industrial Vibration Sensors Circuit Diagram

Industrial vibration sensors help in monitoring vibration issues of systems. As vibration impacts the reliability and durability of the system in working conditions it must be measured. Why Use Industrial Vibration Sensors. Industrial vibration sensors are used to measure and monitor vibration in industrial facilities. They are among the most How to install a vibration sensor? Step 3: Mechanical Installation Mounting Proximitor Sensors. Begin by inspecting the vibration probe, extension cable, and connectors. Look for any signs of physical damage, such as bends, cuts, or wear. If any damage is found, replace the affected parts before proceeding with further tests.

Which industries use the vibration sensor the most? Below is a list of the most common industrial sectors that employ vibration sensors to monitor the vibrations: Aerospace. Automotive & Transportation. Pulp and Paper. Food and Beverage. Oil and Gas, Refining, Petrochemicals. Power Generation (fossil fuel, nuclear, hydro, wind turbines) Machine The sensor should never be mounted on guards, shielding, boxes, covers, or other indirect surfaces. The most effective mounting location is typically at the top and center of the motor, close to the bearing. There are many different approaches to mounting Banner vibration sensors, using brackets with screws, thermal tape, epoxy, or magnets. Vibration sensors have become ubiquitous across industrial sectors owing to their unmatched capability to iden. Introduction A vibration sensor, also referred to as a vibration transducer or vibro sensor, is an electronic device that measures and analyzes vibrations and oscillations in machines, structures, and systems.