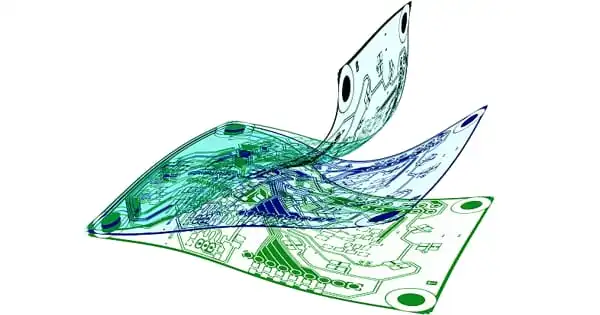

Flexible electronics manufacturing Circuit Diagram

BlogFlexible electronics manufacturing Circuit Diagram As an emerging technology, flexible and stretchable electronics requires the scale-span fabrication of devices involving nano-features, microstructures and macroscopic large area manufacturing. The key factor behind covers the organic, inorganic and nano materials that exhibit completely different mechanical and electrical properties, as well • Next generation flexible electronics systems -Multi-functional electronic sheets for sensing, detection, processing, storage, and communication -Complex integration of various circuit components • Multi-disciplinary effort key to success -Ink and material development -Transistors and interconnect design Additive manufacturing (AM) for printed flexible electronics draws upon a digital design file to deposit material, layer upon layer, to construct 3D-printed electronic components and systems. For AM processes to scale at the industrial level, a series of complex, connected, and data-driven events need to occur.

The concept of flexible electronics has been around for several decades. In principle, anything thin or very long can become flexible. While cables and wiring are the prime example for flexibility, it was not until the space race that silicon wafers used for solar cells in satellites were thinned to increase their power per weight ratio, thus allowing a certain degree of warping.

Dynamic bendable display with sound integration using ... Circuit Diagram

His research interests include the design and manufacturing for flexible electronics, curved electronics, printed display, and metamaterials. By now, he has published 3 monographs and more than 120 papers in international peer-reviewed journals like Science Advances, Advanced Materials, Advanced Functional Materials, Nature Communications, etc. Structural design is a critical approach to achieve high stretchability in flexible electronic devices. Through clever structural design, highly stretchable devices with two- and three-dimensional architectures can be engineered from customary rigid materials and maintain an appropriate level of protection measures against externally applied loads. Flexible electronics, also known as flex circuits, Depending on design requirements, double-sided flex circuits can be fabricated with protective coverlayers on one, both or neither side of the completed circuit, but are most commonly produced with the protective layer on both sides. One major advantage is that it allows easy crossover

The flexible thermoelectric generators were wearable and could be degraded and recycled, which promotes the sustainable development of flexible electronics . Li et al. designed a skin heater by screen printing ink with suitable viscosity on elastic substrates by mixing liquid metals with Cu and polymer, which can work stably under 60% strain